We are proud to be involved in creating new technological solutions in cooperation with well-known and established research and science centers

Research and development projects

Some of projects we have completed

Installation of densimeters

Installation of oscillating densimeters on crude oil transmission pipelines.

The scope of work included:

– execution of design works;

– purchase and installation of densimeters;

– commissioning and validation.

EPC FORMULA

Construction of a steam generator

Participation in the project “Construction of a steam generator for

the commissioning of a unit after a catastrophic failure of the National Energy System”.

The scope of work included:

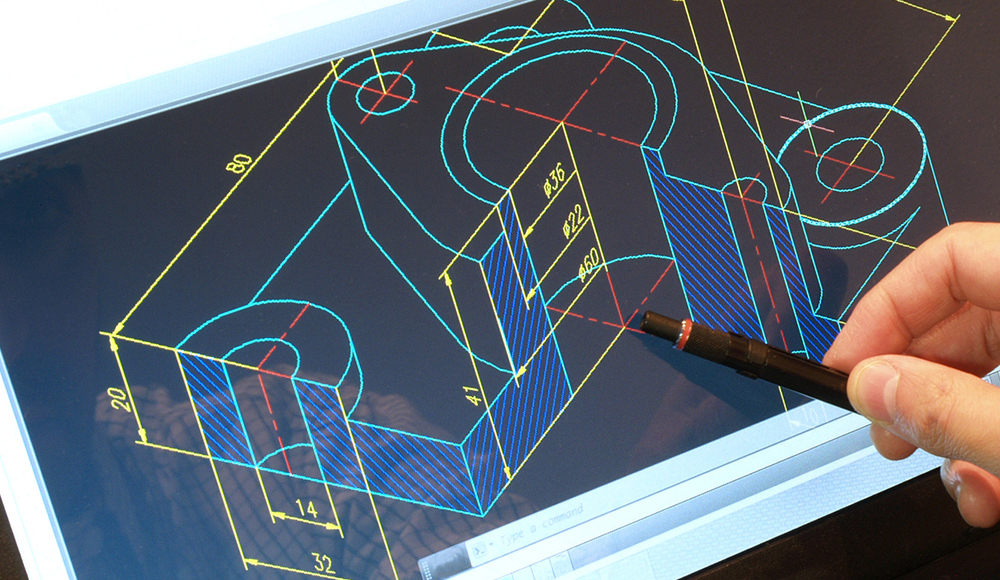

– preparation of design documentation in all industries;

– performing author’s supervision.

E formula (Engineering)

Furnace revamping

Modernization of the Burner Management System of the process furnace with replacement of burners, piping, instrumentation, DCS/ESD.

EPC FORMULA

Boiler revamping

Development of a concept for boiler burners control strategy, HAZOP and SIL analysis, selection of equipment, as well as development of the Technical Attachments to RFP for the modernization of seven boilers of Refinery’s Powerhouse.

E formula (Engineering)

Process analytics

Design and implementation of a on-line process analysis system (14 pcs. of on-line chromatographs and analyzers) for a newly built refinery Metatesis Plant

EPC FORMULA

Process safety

Preparation of instrumentation of process Emergency Shut-Down System (ESD) documentation to adapt interlocking systems to the required level of Safety Integrity Level and extension of the test intervals to 3 years including analysis of HAZOP and SIL validation.

E formula (Engineering)

Explosion protection

Performing of explosion hazard classification analysis, preparation of the documentation for the Explosion Hazard Zones and the “EX Document” for the refinery’s “Powerhouse Plant Complex".

E formula (Engineering)

Technological and Operating Instructions

Development of full complete packet of Operator and Maintenance Instructions for the newly built refinery plant.